carGObis

Boran Software

CarGObis software, designed for airport cargo terminals, will be your most reliable assistant to follow your operational processes.

Our Cargo Management System, which started its life cycle with the first version of BoranSAL in 2004, has been presented to you, our valued customers, with a more functional and user-friendly interface as of 2017. CarGObis general features that perform the functions of the Warehouse Management System are as follows :

- Cargo labels can be printed on the system,

- Acceptance of cargoes to the warehouse with hand terminals, tracking, exit and counting movements within the warehouse

- Creating manifestos

- Linking cargoes to relevant manifests

- Producing documents such as Cargo Manifest, Warehouse List, Porch External List etc.

- Automatic sending of necessary Iata messages after the closing of the Export Manifesto (FFM, FWB, FHL etc.)

- Automatic import of Iata messages sent before the arrival of import cargoes to the warehouse, automatic creation of Manifesto and Bill of Lading (FFM, FWB etc.)

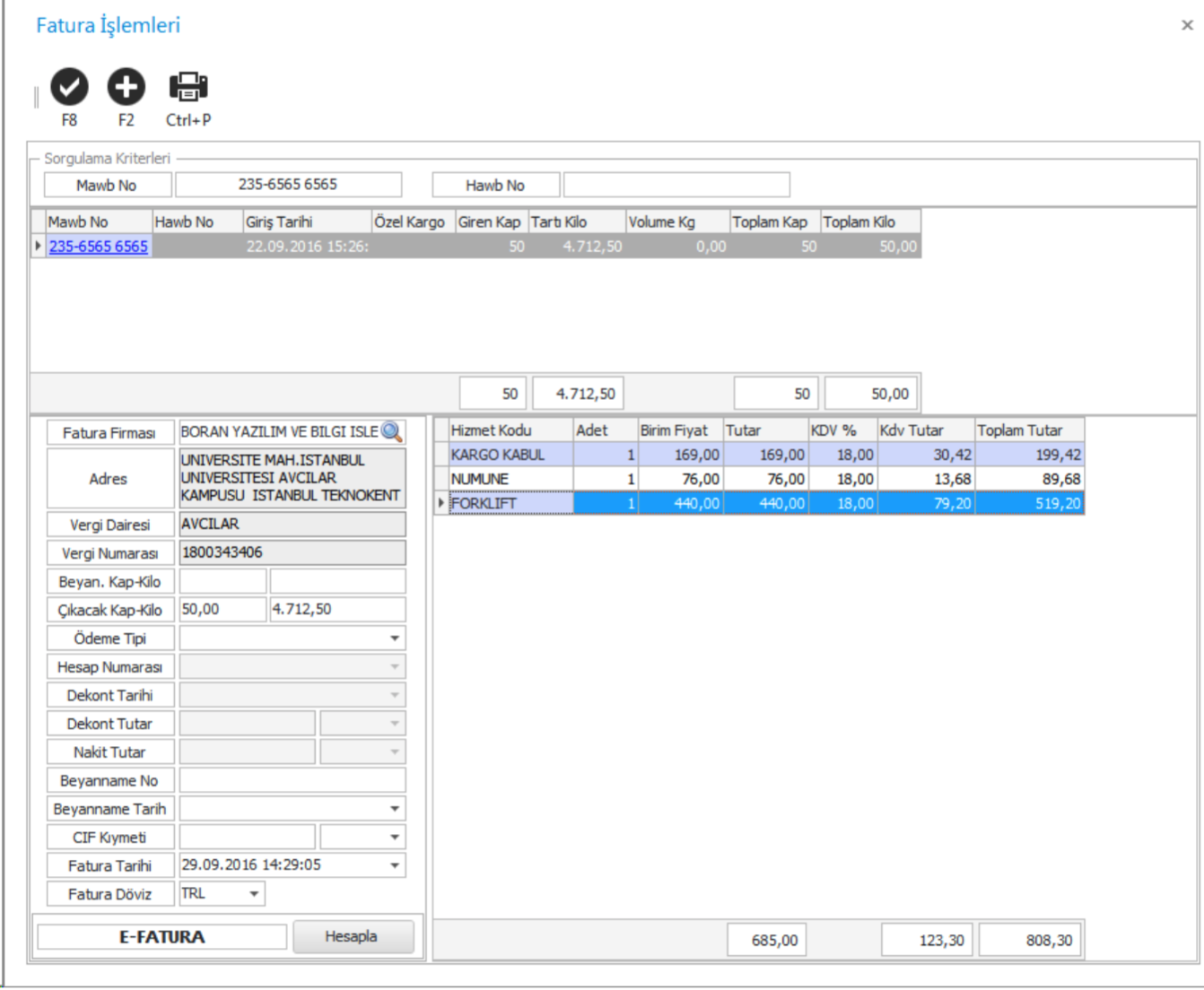

- Automatic creation of import and export invoices in line with the tariffs.

- Integration into E-Invoice and E-Archive systems

- Automatic creation Waybill

- Automatic sending of notification mails to the buyers of imported cargoes in certain periods,

- Domestic cargo operations,

- Transit cargo operations,

- Integration with ETV systems (Lödige,CTI Systems etc)

- Integration with finance systems (SAP vb)

- Daily, monthly, annual operational and management reports

- Periodic cargo value reports (CIF Reports)

Content and Details of the project:

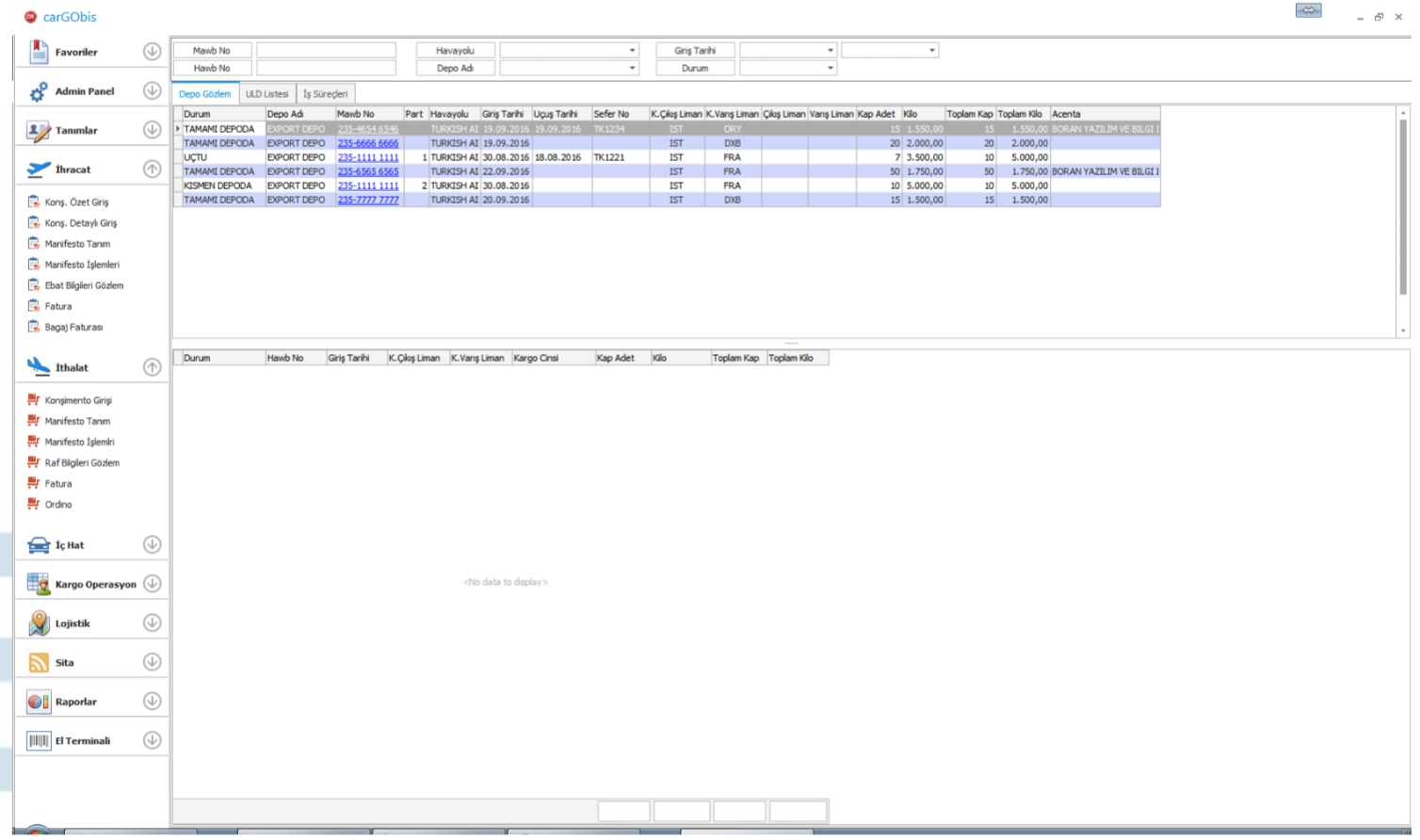

With carGObis, we will enable you to manage your daily workflow in the easiest way and help you meet all the needs of your business. carGObis details are as follows;

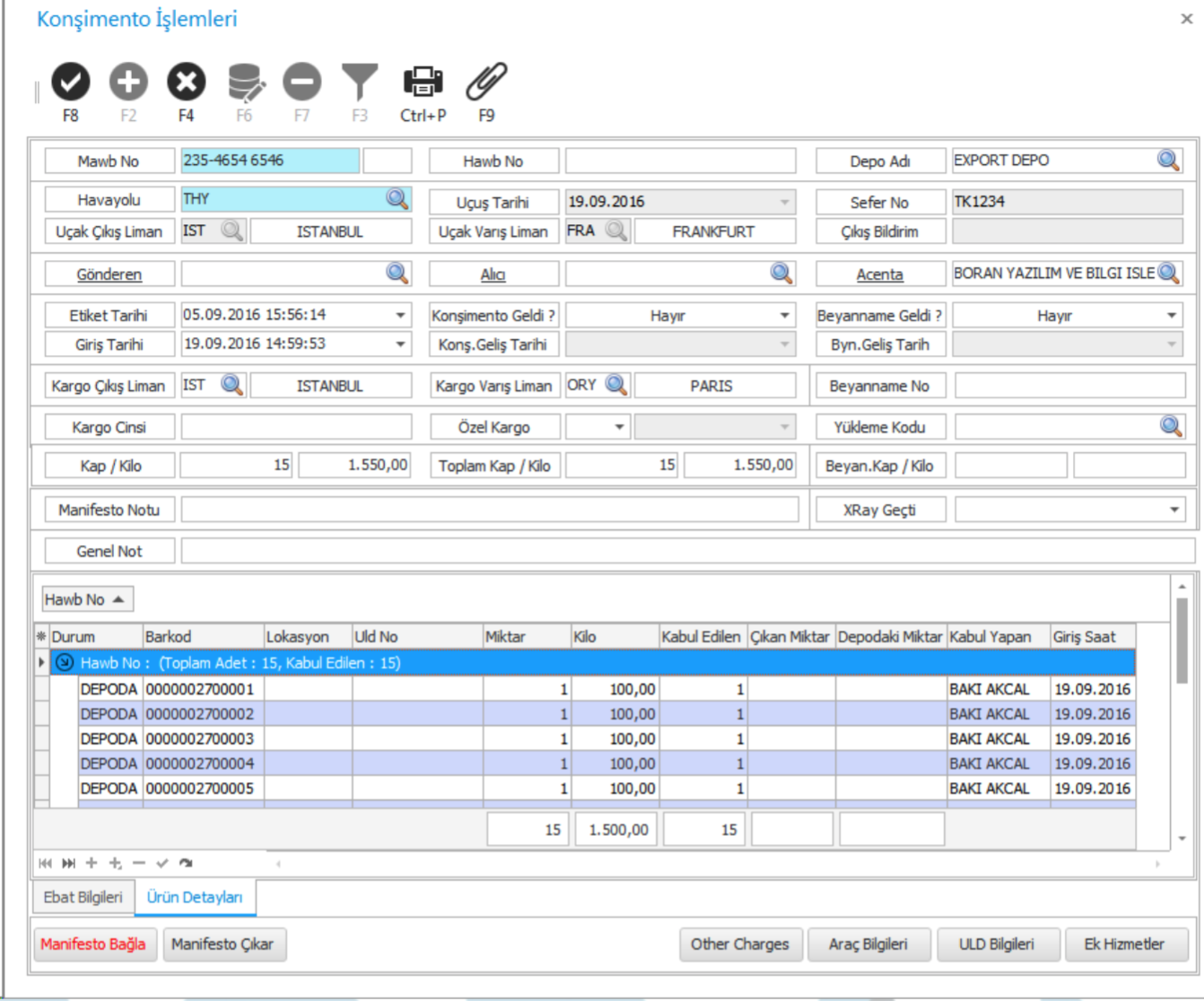

1.Export Cargo Acceptance Process:

- System monitoring of the authorization certificate of air cargo agencies.

- Entering and registering the Name, Surname, Tel and Agency authorization certificate / identification information of the agency personnel during the label acquisition phase. When the same staff comes back, they can be found and selected.

- Checking the suitability of the bill of lading entered on the label, according to the AWB stock tracking system.

- Printing the label and giving it to the agency.

- Acceptance staff reading the barcode of the label with the hand-held tool

- VAL, PER, PER (Fish, Egg, Vegetable / Fruit), HEA, DGR etc. Making elections

- Acceptance staff, if there is damaged cargo at the entrance, take a photograph, read the relevant barcode and send an automatic email to the specified addresses.

- Forklift hizmet seçimlerinin yapılması

- Making additional service (circle, stretch, chest, euro pallet etc.) choices

- Entry of size, container, weight information (based on MAWB, HAWB)

- Automatic sending of FSU / FOH message via SITA at the same time with the hand terminal of the acceptance staff, with all of the size, container, weight information entered.

- AWBs of size, container, weight input are completed and Caljan messages can be sent automatically on the basis of Master and House.

- The personnel who loaded the cargo on the x-ray must read the cargo label (for 1 cargo on 1 euro pallet) by hand terminal and deliver the cargo to the x-ray before putting the cargo on the x-ray,

- The type of goods, AWB, container, x-ray entry time of the cargo that the cargo staff reads is displayed in front of the X-ray operator. (Suppression of “Clean-Opaque-K9” forms)

- The X-ray operator can fill the CSD form automatically over new software when needed. CSD form can be printed.

- Cargoes taken from the back of the X-ray are placed by the cargo staff in certain locations (rack, room, safe etc.) by the hand terminal.

2.Storage, Additional Services and Billing Process

- The storage officer enters the information on the declaration into the system.

- The additional services entered from the handheld terminal automatically drop into the warehouse screen including overtime pay, creating the invoice and sticking stickers on it.

- HAWBs under a single invoice on the basis of MAWB (multiple invoice)

3.Baggage Operations Process

- According to the information in the label form, the production of the luggage label and the baggage acceptance receipt

- Acceptance of baggage from the hand terminal (entering size, weight, type of goods)

- Automatic (Caljan) messages can be sent to the airline as in the cargo acceptance

- Performing operations such as unit loads (counting, warehouse exit, bulk / ULD loading) using the handheld terminal.

- Luggage manifests can be taken in ULD or bulk

- Baggage returning from under the plane (all or as part) to the warehouse can be re-entered with the hand terminal and this situation can be followed

- Creation of baggage bills.

4.Storage, Additional Services and Billing Process

- The declaration and bill of lading accepted by the documents, the details of the documents on the AWB (Master and House basis) are entered into the system.

- If the Master Awbs entry is complete, the message RCS (automatic), FWB (by the optional-cargo officer), FHL (by the optional-cargo officer) should be sent. If the entry to the MAWB and HAWB system is completed, automatically send the bill of lading information to the desired airline as an e-mail.

- It is possible to monitor whether the documents registered in the system are missing or not.

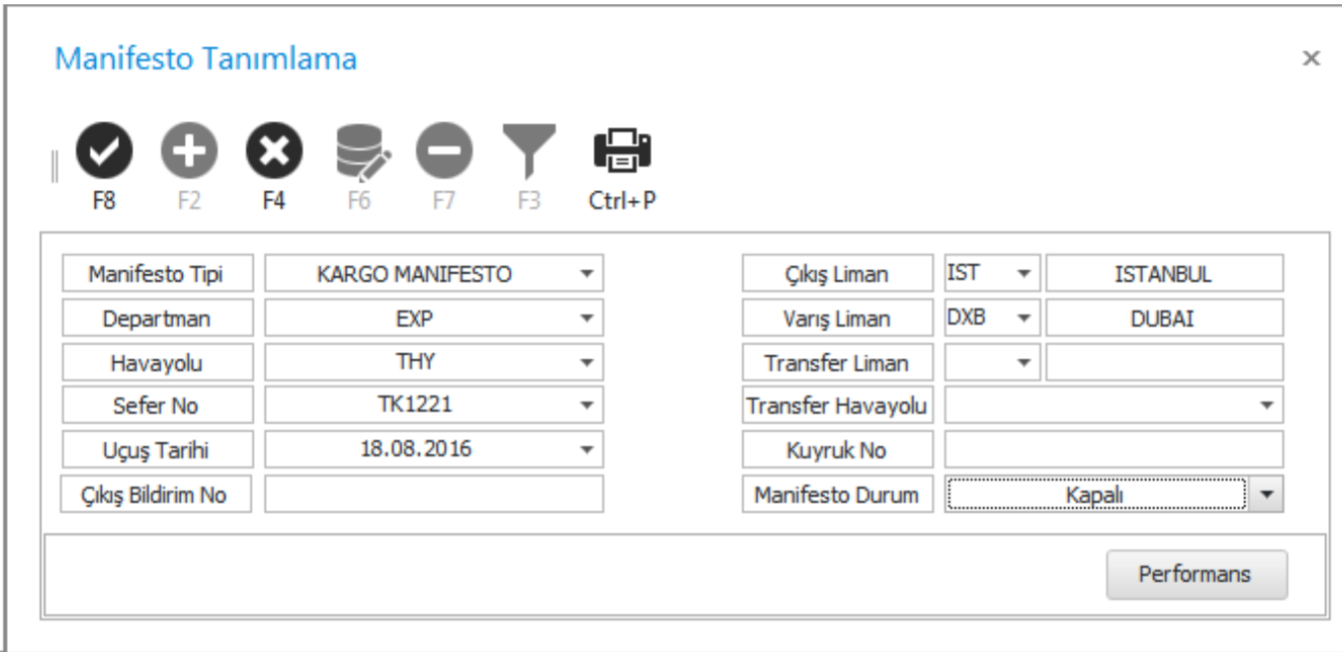

5.General Cargo Palletizing and Airplane Operation Process

- Creation of manifestos.

- Completing the loading of pallets and containers with the hand terminal (Cargo officer enters the hand terminal with pallet, container, car number. When loading related cargoes to ULD, it provides the barcode to be loaded and loaded. completes the ULD installation by entering the number manually).

- If the loaded cargo is more than the weight that the pallet can carry during palletising, the system warns and does not allow to close the pallet with the hand terminal.

- Automatic creation of a record of the remaining part cargo to the system such as part2, part3 ..

- After the aircraft manifest is created, sending the manifest automatically to the relevant units (Operation and Airline) via e-mail.

- Printing of ULD label from hand terminal.

- When removing the cargoes from the warehouse, the aircraft labels are read by hand terminal and exit from the warehouse

- Marking the information that the cargo is under the aircraft and loaded with the hand terminal of the cargo officer under the aircraft and recorded in the system.

- Sending all the loading message (FFM, FWB, FHL, DEP) related to the plane via SITA

- Cargoes sent with an FFM message should be checked out of the export warehouse at the same time.

6. Special Cargo Palletising and Airplane Operation Process

The special cargo palletizing process is the same as the General cargo palletizing process and its different aspects are as follows;

- Automatically filling out NOTOC from the system by entering special codes, data, and printing and sending it via e-mail. Flow of the NOTOC screen when creating a NOTOC by selecting the relevant AWBs in the manifest screen.

- Automatic sending of pre-alert message to the SITA and e-mail addresses of the relevant destinations for the special cargoes connected to the manifest, after the AIRPLANE is gone through the software system.

7. Postal Services Operation Process

- Acceptance of mail with barcode, loading and delivery with barcode

8.Domestic Operation Process

- Domestic manifest identification screen

- Related domestic cargoes can be entered under this manifest and connected to the manifest and the manifesto can be printed

- Daily, weekly, and monthly internal report of internal errors can be obtained.

- FFM message can be sent and e-mailed

- For domestic operations, automatic drop off of cargo from the warehouse when the aircraft is gone.

- Ability to perform domestic manifesto inquiries

9.Import General Cargo Acceptance Process

- Automatic transfer of SITA message from the relevant airline to the cargo management system. FWB, FHL (INTEGRATION)

- Under the aircraft, the cargo operation officer meets the incoming cargo and approves the incoming cargo's pallet number at the hand terminal when it matches the SITA message, if the ULD number does not match the SITA message, the cargo officer sends a warning to the hand terminal by selecting options in different formats.

- By reading the Bulk cargos with the hand terminal (for 1 unit), the number of cargos is confirmed in the system in the event that the number matches the SITA message. If the container quantity is excessive / missing / different, it sends the manifest surplus / minus / damage / manifest external information to the system by selecting options in different formats to the handheld terminal.

- Receipt of warehouse list by import warehouse officer from cargo management system.

- Opening the pallets and containers, loading the cargo on euro pallets and sticking the preprinted unique barcode labels for each euro pallet and matching the loaded cargo with the system.

- In case of loading of more than one bill of lading on a euro pallet, these unique barcodes are glued to each bill of lading, not for europalet.

- In the event that damaged cargo is detected, selecting the damaged option when the relevant cargo is read with the hand terminal, entering the number of damaged containers in the hand terminal and taking a photo of it with the hand terminal.

- Placing the cargo on the shelves with the hand terminal and accepting it to the warehouse.

- First entry of AWBs that are not registered in the system and have access to the warehouse, from the hand terminal.

10.Import Cargo Exit Process

- Creating warehouse invoice, removing and sticking the barcode label

- Collecting the warehouse fee with Ordino, declaration and exit control receipt.

- When the cargo is removed from its shelves for inspection, bosses, etc., it is blocked from the hand terminal to the relevant rack and no new cargo entry can be made to the relevant rack.

- Delivery of cargo according to the shelves in the lowered exits and sending the DLV message to the airline automatically when the container amount on the invoice is equal to the amount. If the system does not match, WARNING.

- When a warehouse invoice is issued, a work order is sent to the exit area.

- Storing / archiving documents of the cargoes to be output (AWB, Ordino, Door exit receipt, Power of Attorney, Declaration).

- Output of cargo from cargo management system with hand terminal

11.Raporlama Süreçleri

- Import Reports

- Import entry report

- Import exit report

- Import stock report

- Import caunting report

- Import liquidation list

- Import performance report (airline, date, voyage number based, contains information on the start / end of pallet unbundling, how many people are done with pallet unwrapping, container, weight, from warehouse entry to exit).

- CIF report ( Qlik view)

- Chargeable weight report

- Import capacity report, occupancy rate (daily, weekly, monthly- Qlik view)

- Company Sales Report (Qlik view)

- Daily Storage Report

- Daily Ordino Report

- Daily Freight Report

- Unsold Ordino Report (buyer information should also appear in the report)

- IRP report (reporting of all cargoes with IRP with their dates)

- Vault Reports (Daily Invoice and Vault Reports can be printed from a single screen, for warehouse and ordino)

- Operation Reports

- Weight reports

- Mail reports

- Domestic reports

- Transit reports

- AWB reports

- Supporting material report (those provided by the airline, invoiced to the airline)

- ULD Stock control reports

- Airplane report (number of planes, type of planes, import export tonnage, number of import export uld)

- Export Reports

- Warehouse counting report

- Liquidation report

- Export entry report

- CIF report

- Baggage reports

- Export performance report (airline, date, voyage number based, includes information on palletizing start / finish, how many people palletizing work is done, container, weight, from the entry of the cargo to the warehouse).

- Export stock report

- Possibility to get the report of all information entered into the system on the basis of Master and House

- Management Report Proccess

- CIF report for both import and export (Qlik view)

- Company Sales Report (Qlik view)

- Import capacity report, occupancy rate (daily, weekly, monthly- Qlik view)

- Income Report (Qlik view)

- Weekly tonnage and income report (Qlik view)

- Revenue, tonnage, ordino performance report (Qlik view)

- Consignee, freight forwarder performance report

- Dwell time report

12.Web site Integration

- Your arrival notification to Ordinoya; Providing the integration flow of import numbers that agency notifications from the system to the warehouse list automatically.

- Access to container weight size information on the basis of MAWB, HAWB of cargo acceptance

13.E-AWB Integration

- New software Cargo-XML adapt

- E-AWB, E-CSD adapt

14.IT Interface and Features

- Application General Structure and Standards

- Application data can also be viewed from the web interface.

- Application database connection etc. parameters can be managed for changes, designed as open parameters.

- Integration applications work in a Service-based structure.

- The application logs all transactions and integrations for troubleshooting.

- Automatic archiving jobs for logging work as a service.

- Admin Interface

- A separate screen access is provided for adding, removing and updating of application, technical and business parameters / standards.

- The admin interface has user access only within specified powers.

- With this interface, it provides the management of the standard and the following parameters used for all applications and integrations,

- Business parameters; units of measure (weight, currency, etc.),

- Calculation functions

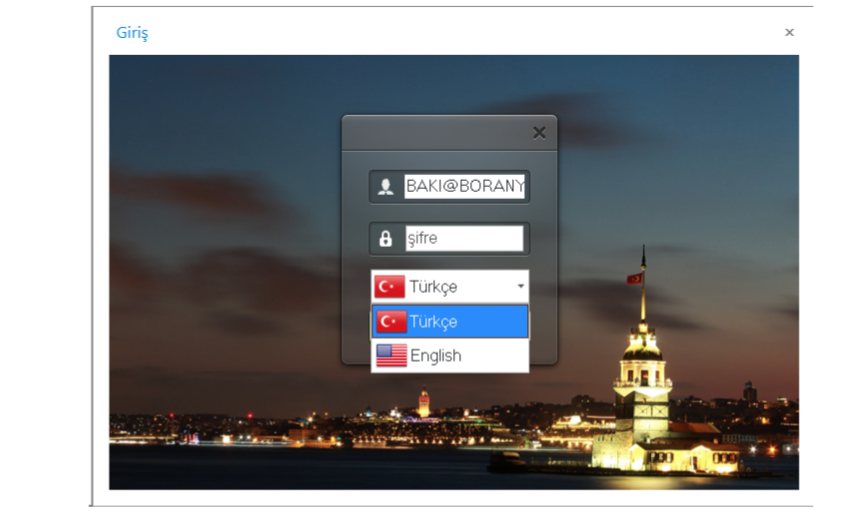

- Technical parameters; User Role / Profile / Name definition etc., role and user authorizations, determination of validity period, etc. IP, Database SID, SQL Sentence, SQL Filters, SMTP IP address, e-mail address for e-mailing, subject title etc. definition of folder paths used for all kinds of logging.

15.IT Interface and Features

- Sita Integration

- Integration works on a service basis and all transactions are logged. (transaction-text file / Database Table)

- Sita Message formats can be updated and changed by the "admin" user for each message type.

- Logging is done for outgoing message, logdetailer sending hostname, windows user name, application user name, date, time etc. contains information.

- SAP Integration

- Integration works on a service basis and all transactions are logged. (transaction-text file / Database Table)

- Logging is done for outgoing message, logdetailer sending hostname, windows user name, application user name, date, time etc. contains information.

- E-Mail Integration (Messaging System)

- E-Mail Jobs run on the server as a service.

- Smtp etc. definitions are defined as open parameters. (lair or table)

- Logs are kept for all transactions.

16.Security

- All database and user passwords are kept as "encyrpt".

- There are expire / active / passive status and times for user accounts and passwords.

- User account login / logout information is logged with detailed information.

- Application Database connection schema name and password are designed as encrypt.

- User authorizations can be made by defining Profiles / Roles for application access.